A slicer is a toolpath generation software used in 3D printing. It facilitates the conversion of a 3D object model to specific instructions for the printer. The slicer converts a model in STL (stereolithography) format into printer commands in G-code format. I wrote my own slicer to understand how they work. Here is what I found out.

Continue readingPost Category → hacking

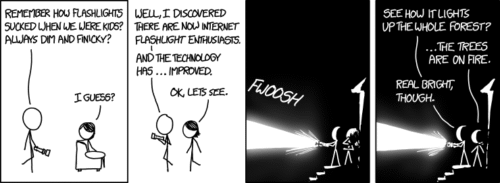

Deconstructing a flashlight

Ever wondered how the modern flashlight works? What happens when you click the switch on, or click it multiple times to change the brightness? I was curious about it as well, so I deconstructed a commercially available flashlight (Astrolux S1) and studied the parts; even reprogrammed it to have different levels of brightness. Here is what I found out.

Continue readingMarlin 3D printer firmware: Delta inverse kinematics

With a simple cartesian printer, the carriage mechanism moves directly along rails in each of the x, y and z directions. If you want to move a print head from the origin to, say, (10,10,20) you simply direct the motors to move it 10mm along the x axis rail, 10 along the y axis rail and 20 along the z. With a delta printer, it’s not so simple. Moving any one of the carriages which run up and down the three vertical towers will cause movement of the printer nozzle in x,y and z simultaneously. Inverse kinematic calculations are required to work out how to move all three carriages to move the print head to the given (x,y,z) coordinates.

Continue readingDissecting the ErgoDox – The Ergonomic Programmable Keyboard

Invented by Dominic Beauchamp (a.k.a Dox), the ErgoDox is an ergonomic mechanical keyboard that uses an open hardware and software. This keyboard uses a split design that allows your arms to rest naturally at your sides. The split also allows you to angle the boards and doesn’t force you to contort your wrists. The keyboard is also fully programmable. Lets find out how it actually works.

Continue reading